Automatic V Fold Paper Towel Making Machine With Embossing System

Specification for V FOLD Paper Towel Machine_20210...Specification for V FOLD Paper Towel Machine_20210...

Description

Automatic V Fold Paper Towel Making Machine With Embossing System is used to make V Fold Hand Towel with embossing and cutting off the towel paper .The folding of product is “C” type folding .This kind of towel paper is used widely in hotel, office and kitchen etc, that is convenient and sanitation. We adopt original creation full vacuum absorption technology, the adaptability of raw material is so strong .The folding, cutting ,counting etc several processes are going together.

Function and Features

1- Adopts vacuum suction technology (Patented). Most of the technology is exceed other countries technology standard.

2- With inverter (DELTA/MITSUBISHI/SIEMENS) to regulate the working speed

3- With detector, stop automatically when paper break or run out

4- Pneumatic parent roll loading, web tension controlling to guarantee stable high speed running

5- Equipped with embossing system, pneumatic paper separating.

6- Equipped with Roots Type vacuum pump for stable running of the machine.

7- With jogging button and Emergency button on machine

8- With timing belt and gearbox transmission, which is suitable for various of parent rolls’ quality

9- Can set working date on HIM interface

10- Add the lubricate oil on key part regularly, for keeping the durability of parts (optional)

11- Power supply: 380V, 60Hz,3phase

Technical Parameters

|

Max width

of raw paper

|

910/1500/2050

|

|

Output direction cutting length

|

180/190/195/200/210, other sizes to be specified

|

|

Speed

|

130m/min(1300sheets/min/lane)

|

|

Operation speed

|

100m/min (1000sheets/min/lane)

|

|

Max outer diameter

of raw paper

|

1500, other sizes to be specified

|

|

Web feeding protection

|

Automatic web thickness monitor

|

|

Upper blade structure

|

Patent-tech spiral blade cutting structure

|

|

Bottom blade structure

|

Patent-tech with suction holes at the blade edge

|

|

Drive type

|

separated drive

|

|

Procedure control

|

PLC

|

|

Folding type

|

V fold

|

|

Options

|

|

*Backstand

|

2~4 ply (plies), to be specified

|

|

*Embossing

|

steel to steel steel to felted , steel to paper woolen , steel

to rubber , to be specified

|

|

*Lamination

|

multiple type, please specify

|

|

*Side trimming system

|

Patented trimming top blade structure,vacuum system removes trimming paper

|

|

*Counting

|

Malposition/ink counting, please specify

|

|

*Edge-embossing

|

pneumatic,integrated counter-roller

|

|

*Web-tension control

|

Dancing roller,fully automatic control

|

1.1 Raw tissue paper:

- Parent rolls size: Ø1200mm*1250mm (diameter*width);

- Tissue character: 35-45gsm, single ply wet strengthen wood pulp paper, good air permeability

- Inner core diameter: Ø76mm

1.2. Tissue paper feeding unit:

- One set paper stand, flat belt for feeding paper (pneumatic),

- Pneumatic paper-mounting unit

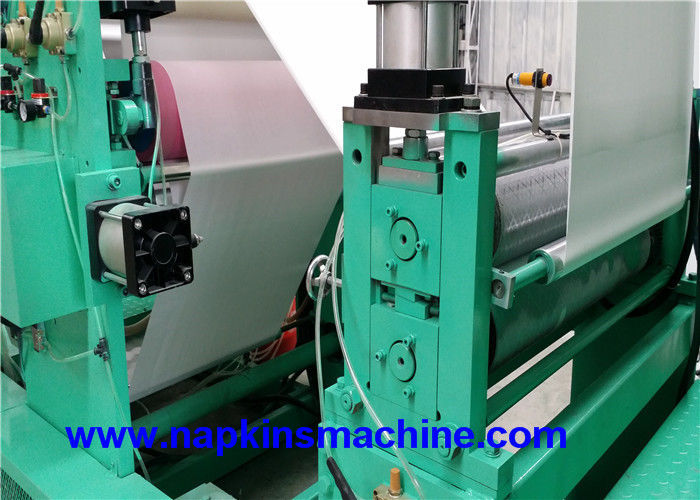

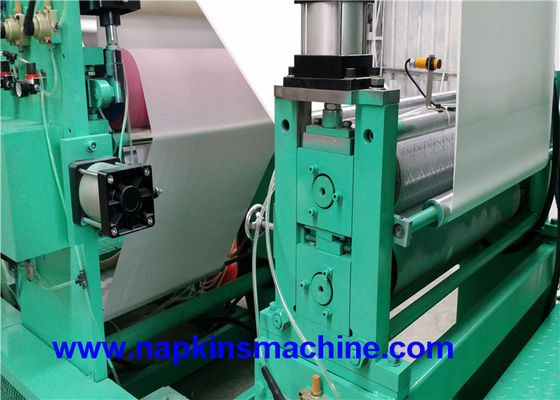

1.3. Embossing unit:

- One set steel roll against steel roll (the pattern as per customer’s requirement.)

- Pneumatic pressing unit

1.4. Folding unit:

- Rotary blade cutting unit (upper blade is fixed)

- Counting function (ink point for counting)

- Folding type: vacuum-absorbing M-fold

- Open size: 240*240±2mm

- Folded size: 240*65±2mm*5lanes

- Capacity: 700 sheets/min*5lanes

- Electrostatic neutralizer unit

1.5. Controlling unit:

- Inverter for main machine

- Roots vacuum pump, includes muffler device

- Emergency function, if tissue is broken, machine stop

- Power supply: 380V, 50Hz, 7.5Kw(main machine) 22Kw(vacuum pump)

- Compressed air: ≥0.55Mpa (supplied by buyer)

This machine is to make N fold or Multifold paper hand towel, for one ply towel, it just needs one back-stand to put one parent roll, this is different from the V fold towel machine, for V fold towel machine, without glue laminator, it needs normally two back-stands;

We can adopt pneumatic system for embosser for easy operation;

If the clients need, we can adopt individual driving system for the back-stands, embosser and head of machine;

For this machine, normally at least need to make it in 3lanes;

The full package of service we provide: layout of machine and your workshop, help to make erection, commissioning, and train the workers etc.

Working Procedure: Embossing → cutting → N-folding

The finished products can be easily drawn out one after another from the dispensers or packing boxes.

Main Features:

1)Adopts vacuum suction technology (Patented). Most of the technology is exceed other countries technology standard.

2)With inverter (DELTA/SIEMENS/MITSUBISHI) to regulate the working speed

3)With detector, stop automatically when paper break or run out

4)Pneumatic parent roll loading, web tension controlling to guarantee stable high speed running

5)Equipped with embossing system, pneumatic paper separating.

6)Equipped with Roots Type vacuum pump for stable running of the machine.

7)With jogging button and Emergency button on machine

8)With timing belt and gearbox transmission, which is suitable for various of parent rolls’ quality

9)Can set working date on HIM interface

10)Add the lubricate oil on key part regularly, for keeping the durability of parts (optional)

11)Power supply: 380V, 60Hz,3phase

Main Parameters:

| Machine Model |

SYM-NZ-2L |

SYM--NZ-3L |

SYM--NZ-4L |

SYM--NZ-5L |

SYM--NZ-6L |

SYM--NZ-7L |

SYM--NZ-8L |

| Parent Roll Width |

460mm |

690mm |

920mm |

1150mm |

1380mm |

1610mm |

1840mm |

| Unfold Size of Hand Towel |

230×230mm (other sizes can be customized) |

| Folded Size of Hand Towel |

76.6×230mm (with ±2mm tolerance) |

| Parent Roll Diameter |

≤Φ1200mm (other sizes can be customized) |

| Core Dia. of Parent Roll |

Φ76.2mm (other sizes can be customized) |

| Speed |

160~200m/min. |

| Embosser |

Steel to steel |

| Grammage of Raw Paper |

30~45GSM |

| Slitting System |

Full slitting or dot slitting(we suggest dot slitting) |

| Lubricating System |

Automatic key parts regular lubricating (optional) |

| Driving System |

Gear and timing belt |

| Unwinding Unit |

One pneumatic lifter/loading unit for one parent roll |

| Counter |

Ink marking |

| Driving Power |

Frequency conversion speed regulator 6~7 KW |

| Vacuum System |

5.5~8KW(depend on final configuration) |

| Pneumatic System |

5.5 KW Air Compressor (prepared by customer) |

| PLC Control System & HIM |

DELTA/SIEMENS/MITSUBISHI |

| Dimension(L×W×H) |

3000×1300~2000×2500mm (depend on final configuration) |

| Weight |

2000~4100kg (depend on final configuration) |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!