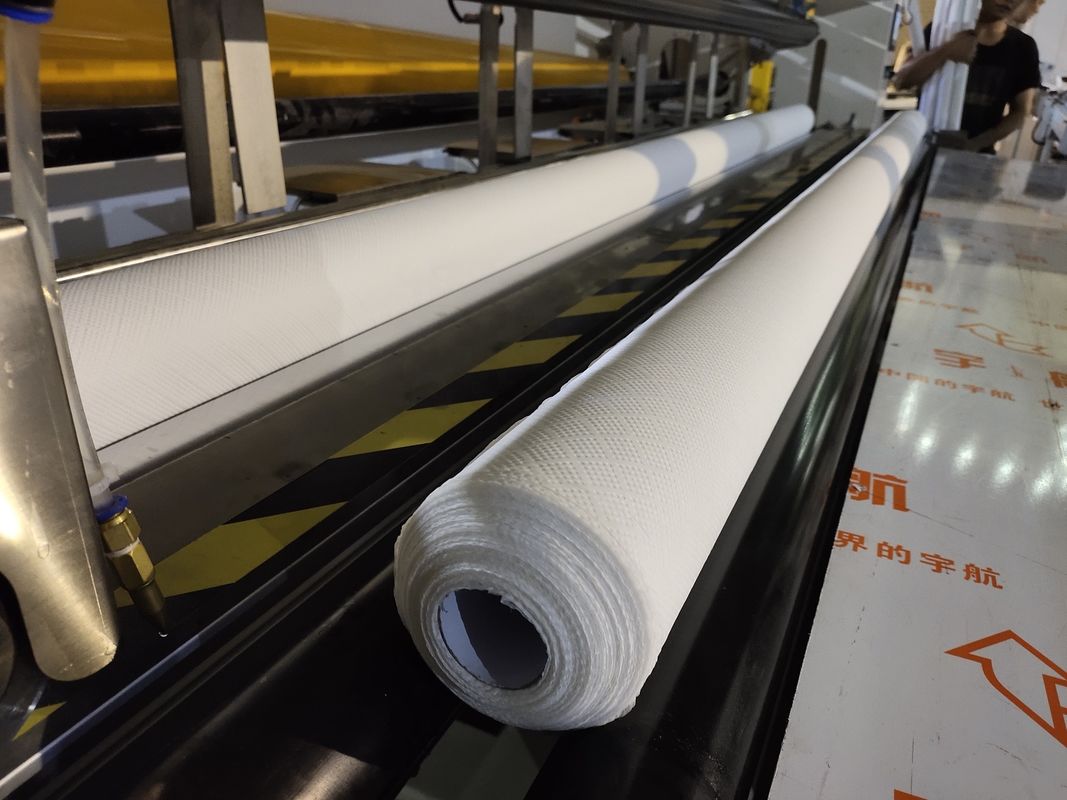

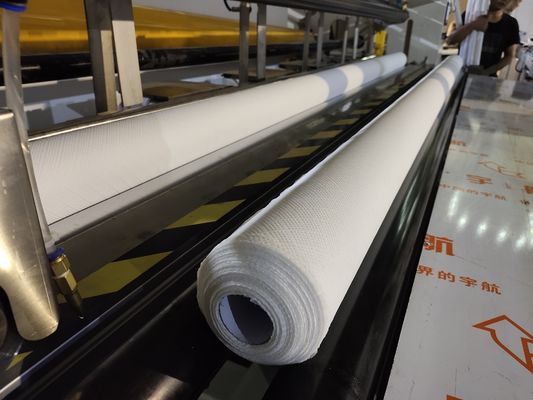

Perforated Paper Cutting Jumbo Roll Slitting Machine , Toilet Paper Rewinding Machine

Description

Mini Jumbo Toilet Tissue Slitting Rewinding and Perforating Machine is to perforate and cut the raw paper into various sizes according to the requested. The finished

product is neat, in good order and with equality tension. It has the feature of compact structure, easy and

stable operation,

less electricity consumption and covers a small area of 8.4 m². The highest production speed is 120-

160m/min. This equipment is adjustable to meet the requested finished product. This model is the ideal

equipment for paper making factory and paper processing factory.

This equipment can process raw paper of 1.2m 1.5m 1.75m 1.95m 2.15m 2.35m 2.55m 2.75m in width.

There are two types of this model: one is ordinary type, it used one embossed unit for 2 ply paper, and

the other is dot-by-dot type, it used embossed units respectally for each one.

This machine is consist of stand of raw material, paper conveying unit, embossing unit, perforating unit,

rolling unit, electricity control and cutting system. The production process is : unreeling —→ embossing

—→perforating—→furl—→slitting.

Specification

|

Model

|

1092mm

|

1575mm

|

1760mm

|

1880mm

|

2400mm

|

2800mm

|

|

Width of jumbo

paper roll

|

1300mm

|

1800mm

|

2000mm

|

2200mm

|

2350mm

|

2700mm

|

|

Diameter of jumbo paper roll

|

1100mm (other size please specify, max. diameter is 2500mm )

|

|

Core diameter of jumbo paper roll

|

76.2mm (other size please specify)

|

|

Programming controller

|

PLC computer programming

|

|

Embossing

|

Single-deck & double-deck embossing, embossing of steel face steel, pneumatic embossing (please specify)

|

|

Embossing roll

|

Felt roll, rubber roll etc ( at seller’s option )

|

|

production capacity

|

150-180meter/min

|

|

Diameter of finished paper roll

|

90—135mm (other size please specify)

|

|

Unreeling stand

|

1-3 layer

|

|

Motor

|

5.5-11KW

|

|

Overall weight

|

3-5Ton

|

Functions and Features

1. Advanced PLC computer programming technology is applied to full automatic toilet paper rewinding machine. The winding profiles can be tight at the beginning of winding, and then getting loose, to avoid the problems that the cores are loose from the rolls after long time storage.

2. It is equipped with frequency control, electronic brake(EABS), and touch-screen interface operation system. Automatic trimming, gluing, sealing, punching, auto feeding, removing shaft and squashing are integrated in one. Ensuring lower consumption when the roll paper is feed into band-sawing machine. So products are of high grade and high efficiency.

3. It is equipped with coreless rewinding system, reducing labor costs, making products more beautiful.

4. With high precision screwy perforation knife. With 4 perforation blades to make low noise and high definition when perforating. The perforating pitch is controlled by gearbox.

5. Automatic detection of paper break and wrap up, to guarantee the high quality of the finished rolls even in the high speed operation.

6. Coreless rewinding system has changed traditional method to take out the core to make high quality solid coreless roller. Reducing the manpower.

7. With three-layer horizontal unwinding stand, pneumatic feeding system. Each roll of raw paper has its individual control unit for tension adjusting device.

8. The web can be threaded on the machine by the two jog buttons, it is more safe and easier to feed the web.

Factory Sale Low Price Tissue Paper Production Line Toilet Paper Making Machine For Sale

Features:

Automatic High Speed Toilet Paper/ Maxi Roll Rewinding Machine is for toilet paper roll/maxi roll processing.

Machine have core feeding unit, can do both with and without core. Raw material from jumbo roll after full embossing or edge embossing, then perforation, end cutting and spray the tail glue become a log. Then it can working with cutting machine and packing machine to become the finished products. The machine is controlled by PLC, people operate it through touch screen, the whole process is automatic, easy to operate, lower the man cost. And Our machine can special-made according to clients' requirements.

|

Model

|

1092B

|

1575B

|

1760B

|

2150B

|

2200B

|

2500B

|

2800B

|

|

Jumbo Roll Max. width

|

1350mm

|

1750mm

|

1880mm

|

2000mm

|

2150mm

|

2400mm

|

2750mm

|

|

Max. Jumbo Roll diameter

|

2-3 stands (pls specify when order)

Paper gram weight 13-16 g/m2

|

|

Jumbo Roll Standings

|

Standardφ3"(76.2mm) (Other sizes specified)

|

|

Data setting

|

HMI

|

|

Programming controller

|

PLC, touch screen

|

|

Operate Speed

|

0-230m/min 15000-25000 rolls/8hours

|

|

Finished Log Outer dia.

|

φ90-140mm

|

|

Finished Log Inner dia.

|

φ38-76mm

|

|

Perforation Distance

|

100-150mm

|

|

Mechanical driving

|

Driving by Stepless gear box

|

|

Air -system

|

3HP air compressor, min. pressure 5kg/cm2pa ( provide by user)

|

|

Main driving

|

Frequency conversion speed regulation 7.5-15KW 380V,50HZ

|

|

Embossing unit

|

Steel to rubber

|

|

Dimensions

|

6x3x1.7 (length x width x height);(m)

|

|

Weight

|

3T-4T(depends on the Model you have )

|

|

Options:

|

|

|

Embossment Roller

|

Plane, Single Set, Double Sets Can be ordered

|

|

Color Printing Unit

|

1-2 Colors can be order

|

|

Lamination Unit

|

Can be Ordered

|

|

Edge-Embossing Line

|

Steel to Steel Operate by Pneumatic

|

Deco Color Lamination Parts:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!